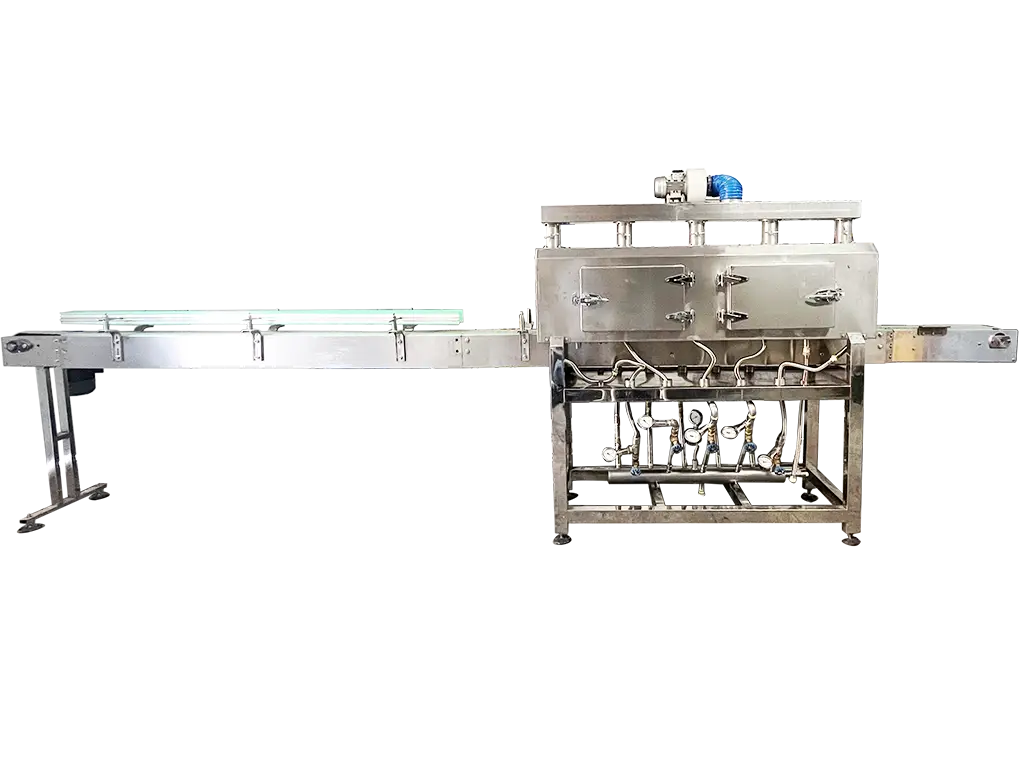

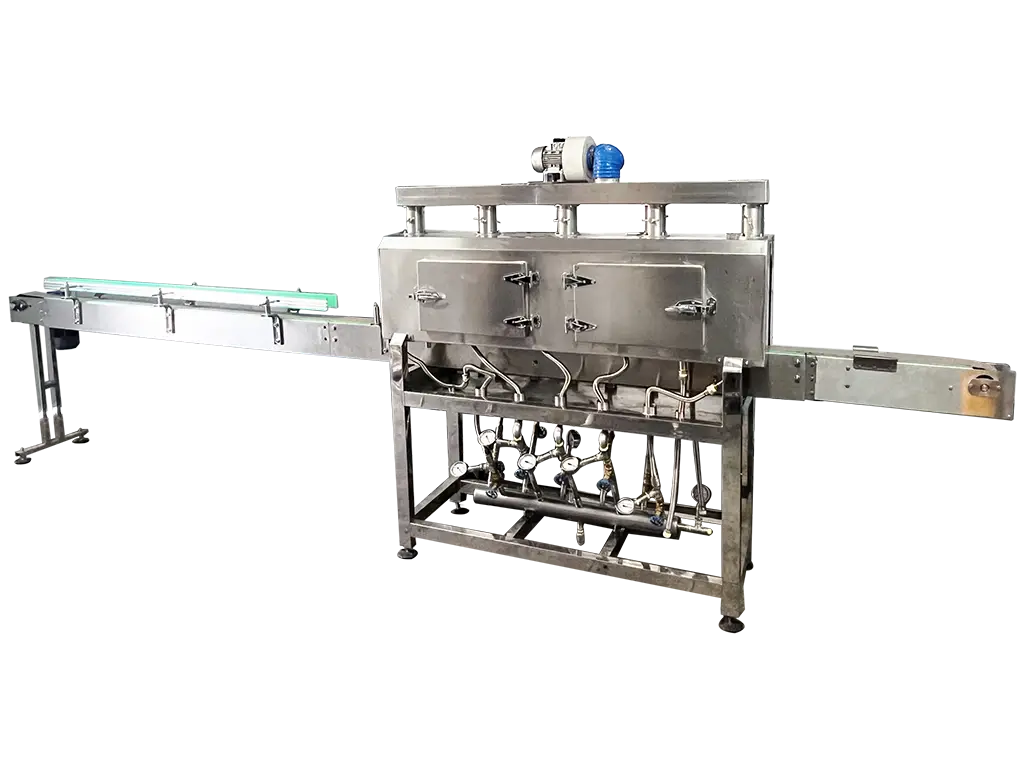

Shrink Tunnel

SNL - SHRINK TUNNELThe Steam Tunnel heats the plastic films placed on the products with steam and ensures that they stick to the packaging. At the same time, the products are sterilized by coming into contact with high-temperature steam while passing through the steam tunnel. In this way, the shelf life of the products is extended and they become safe for health.

There are a total of 6 adjustable deflectors (3 right and left) in our steam tunnel and each deflector can be adjusted up/down, in/out to direct the steam directly to where it is needed in your product. Each deflector has a valve. If you do not need too much steam in a certain area, the amount of steam can be reduced with the valve.

The width and length of the Steam Tunnels are designed and produced according to the film to be used on the packaging and the desired production speed.

- + Conveyor speed can be adjusted with PLC Screen.

+ It can work compatible with Sleeve Machine.

+ Water collection tray with discharge system

+ Steam Nozzles can be adjusted right/left, up/down.

+ It works with generator.

*Required generator power: 85 kW (may vary according to product features)

+ The belt systems used are long-lasting and completely suitable for food.

+ Packaging Types: Glass, Plastic, PET, PE, PP

+ Packaging Features Maximum Diameter: 130mm | Height: 130mm

- + 304 ASIS Stainless Body and Chassis

+ Works with blower.

+ 8 Steam Nozzles (The required steam for each nozzle can be adjusted with the valve.)

+ Works with 4 Bar air.

+ PLC Touch Screen and Control Panel

+ Emergency Button and Lamp

+ Dimensions; Height 1 mt | Width: 1m | Length: 4 mt | Weight: 120 Kg

Steam Tunnel Features

Shrink Tunnel Production Capacity

Working capacity of Steam Tunnel(Shrink)

- 1 Hour / 15,000 - 20,000 Pieces of Packaging

- It varies depending on the size and characteristics of the film to be used and the packaging to be applied.

About Shrink Tunnels

The purpose of Shrink and Steam Tunnels is to stick film on glass or plastic bottles, containers, buckets, etc. with high heat. After this process, the packaging has a coating. At the same time, since the coating is applied to the packaging, the shelf life of the products is extended. Another benefit of Steam Tunnels is that the products are sterilized because they are exposed to high heat.

The Steam Tunnel works independently or as part of a packaging line.

With the Sleeve Machine, the packages (bottle, cup, bucket, etc.) covered with film are carried to the steam tunnel by conveyor, high heat is applied to the packages entering the steam tunnel, the film on the package heats up, wraps the package and sticks to the package.

Steam Tunnels are a machine used in the packaging sector. It is used by medium-sized companies as well as high-level production companies. It is used in the packaging of many products such as Medical, Food, Beverage, Chemical, etc.